The East Calgary Regional Waterline is a 42 kilometer pipeline intended to supply clean, treated drinking water to southern Alberta communities such as Chestermere and Strathmore. As construction nears completion, groundwater infiltration is starting to occur in below-grade manhole chambers built in areas with high water tables.

When groundwater floods manhole chambers, pipeline maintenance becomes much more expensive. The water has to be vacuumed out before a crew can enter the chamber and do their work!

The choice: fix it now or fix it later

Design engineers identified locations on the pipeline that would experience substantial groundwater infiltration. Rather than bother with costly remedies to post-construction water leaks and infiltration issues, they consulted with Martech’s technical sales team and decided to include PSI Riser-Wrap in their contract specification requirements for “water-tight” manhole chambers.

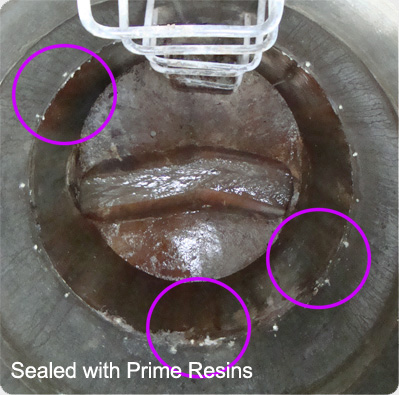

The “tight” chambers were achieved by applying Pipeline Seal and Insulator (PSI) Riser-Wrap around the entire chamber. This complete seal will prevent infiltration through the joints as well as weeping infiltration through the concrete itself. Martech trained contractor personnel in applying the product and proper installation techniques.

Once the project started, a fresh challenge arose. A steel safety cage was required to prevent trench walls from sloughing back on the excavation. This cage only left 30cm of clearance for crews to install the Riser-Wrap!

How did they seal the chambers with Riser-Wrap only 30cm of available clearance?

After consulting with PSI technical experts, a solution was devised:

1.Primer was applied using a long handled roller by personnel on top of the chamber.

2.Next, four strips of 280mm wide Riser-Wrap were used per rotation around the chamber, one on each of the four sides.

3.Riser-Wrap Joiner Strips were used to hold each of the sections of Riser-Wrap together.

4.A propane torch with a handle extension was used to apply heat to the Riser-Wrap and bond it to the primer and chamber exterior.

5.To ensure a positive bond to the concrete, an installing contractor accessed the narrow area between the cage and the chamber to smooth out the edges of the Riser-Wrap.

In all, 12 rolls of PSI Riser-Wrap were needed to put one of the dry chambers into service. Martech was pleased to work with the finest Alberta engineers, contractors and distributors on this project.

Will Riser-Wrap work for your underground infrastructure?

Contact Martech’s Infrastructure Sales team and ask if Riser-Wrap is the right choice to seal your project’s below-grade chambers.